Which Cars Have LFP Batteries?

An ever-growing list of EVs powered by LFP batteries.

An increasing number of EVs have LFP batteries.

Production efficiencies have made Lithium Iron Phosphate (LiFePo4) batteries the preferred choice for many EVs.

While LFP batteries are cheaper, they lack the energy density of NMC chemistry. For this reason, they are often used in lower-range models.

However, this is changing quickly, with a growing number of longer range vehicles using LFP.

EVs with LFP batteries (international)

This sortable list is updated frequently and lists models available in the European, Australian, (+ some from the USA) markets. Model and trim names can vary between regions.

← Swipe to scroll horizontally →

Model | Shape | Battery | WLTP Range |

|---|---|---|---|

BYD Atto 2 | SUV | 45.1 kWh | 312 km |

BYD Atto 2 Extended | SUV | 64.8 kWh | 420 km |

BYD Atto 3 (base) | SUV | 50 kWh | 345 km |

BYD Atto 3 Extended | SUV | 60.5 kWh | 420 km |

BYD Dolphin | Hatch | 44.9 kWh | 340 km |

BYD Dolphin Extended | Hatch | 60.5 kWh | 427 km |

BYD Dolphin Surf 30 | Hatch | 30 kWh | 229 km |

BYD Dolphin Surf 43 | Hatch | 43.2 kWh | 310 km |

BYD Dolphin Surf 43 Boost | Hatch | 43.2 kWh | 322 km |

BYD Seal (base) | Sedan | 61.4 kWh | 460 km |

BYD Seal Performance | Sedan | 82.6 kWh | 520 km |

BYD Seal Premium | Sedan | 82.6 kWh | 570 km |

BYD Seal U | SUV | 72 kWh | 420 km |

BYD Seal U 87 | SUV | 87 kWh | 500 km |

BYD Sealion 7 AWD | Large SUV | 82.5 kWh | 456 km |

BYD Sealion 7 AWD Perfomance | Large SUV | 91.3 kWh | 502 km |

BYD Sealion 7 RWD | Large SUV | 82.5 kWh | 482 km |

Citroen e-Berlingo | Van | 50 kWh | 345 km |

Citroen e-C3 | Hatch | 44 kWh | 320 km |

Citroen e-C3 Aircross | SUV | 44 kWh | 306 km |

Citroen e-C3 Aircross extended | SUV | 54 kWh | 400 km |

Citroen e-C3 Urban Range | Hatch | 30 kWh | 212 km |

Dongfeng Box 31.4 | Hatch | 31.4 kWh | 230 km |

Dongfeng Box 42.3 | Hatch | 42.3 kWh | 310 km |

Fiat Grande Panda | Hatch | 44 kWh | 320 km |

Firefly EV | Hatch | 42.1 kWh | 330 km |

Ford Mustang Mach-E SR AWD (2024+) | SUV | 72.6 kWh | 470 km |

Ford Mustang Mach-E SR RWD (2024+) | SUV | 72.6 kWh | 470 km |

Geely EX5 | SUV | 60.4 kWh | 425 km |

GWM Ora | Hatch | 45.4 kWh | 310 km |

GWM Ora 07 (base) | Sedan | 67 kWh | 440 km |

Jaecoo 5 EV | SUV | 58.9 kWh | 399 km |

KGM Torres EVX | SUV | 73.4 kWh | 462 km |

Kia EV5 2WD* | SUV | 84 kWh | 540 km |

Kia EV5 AWD* | SUV | 84 kWh | 500 km |

Leapmotor B10 Base | SUV | 56.2 kWh | 361 km |

Leapmotor B10 Extended | SUV | 67.1 kWh | 480 km |

Leapmotor C10 | SUV | 69.9 kWh | 420 km |

Leapmotor T03 | Hatch | 41.3 kWh | 265 km |

Mazda 6e (base) | Sedan | 68.8 kWh | 479 km |

MG 4 (base) | Hatch | 50.8 kWh | 350 km |

MG IM5 (premium) | Sedan | 75 kWh | 490 km |

MG IM6 (premium) | SUV | 75 kWh | 450 km |

MG S5 EV 49 | SUV | 49 kWh | 340 km |

MG S5 EV 64 | SUV | 64 kWh | 463 km |

MG ZS EV | SUV | 49 kWh | 320 km |

Omoda E5 | SUV | 61 kWh | 430 km |

Opel Combo e-Life | Van | 50 kWh | 345 km |

Opel Frontera | SUV | 44 kWh | 305 km |

Opel Frontera extended | SUV | 54 kWh | 408 km |

Smart #1 Pure (base) | SUV | 47 kWh | 310 km |

Suzuki eVitara | SUV | 61 kWh | 426 km |

Suzuki eVitara (base) | SUV | 49 kWh | 344 km |

Tesla Model 3 (2019-2023) | Sedan | 60 kWh | 491 km |

Tesla Model 3 (2024+) | Sedan | 60.9 kWh | 513 km |

Tesla Model Y | Sedan | 60 kWh | 455 km |

Toyota Urban Cruiser AWD | SUV | 61.1 kWh | 395 km |

Toyota Urban Cruiser FWD | SUV | 61.1 kWh | 426 km |

XPeng G6 AWD Performance | SUV | 80 kWh | 510 km |

XPeng G6 RWD Long Range | SUV | 80 kWh | 525 km |

XPeng G9 AWD Performance | SUV | 92.2 kWh | 540 km |

XPeng G9 RWD Long Range | SUV | 92.2 kWh | 585 km |

XPeng G9 RWD Standard | SUV | 78.2 kWh | 502 km |

Zeekr 7X Premium AWD** | SUV | 75 kWh | 480 km |

*The Kia EV5 has LFP only in some markets (if the car is manufactured in China)

** Zeekr uses the new Golden battery (5.5C charging).

Which Teslas have LFP?

Only some Model 3s manufactured after September 2021 have LFP. Tesla publishes very little data on batteries used in vehicles.

To check, go to the charging screen:

- If it has an option for a 100% charge limit, the car has an LFP battery.

- You can also check the VIN. If the 7th character is an F, it is LFP (source in German).

Which Ford Mustang Mach-E EVs have LFP?

From the Mach-E manual:

- If the 8th VIN digit is a 4 or 5, you have a Lithium Iron Phosphate (LFP) battery, and if there is any other digit or letter, you have the Nickel Cobalt Manganese (NCM) style battery.

What new LFP batteries are in the pipeline?

Press releases do not guarantee a battery pack in a production car. However, for some newer batteries, production efficiencies do result in improvements in EV range and price.

- CATL launched the Shenxing Pro in late 2025. An LFP battery with exceptional performance in cold, over 800 km of range, superfast charging (478 km in 10 minutes).

- Geely's short blade battery - 192 Wh/kg - to be used in Geely EVs.

- Joint venture between SAIC and GM launches a 6C charging LFP battery.

- LG will provide LFP batteries to Renault group (Ampere).

- Svolt started production of new short blade battery. It has 188 Wh/kg, 5C charging, and a lifespan of 3,500 cycles. Svolt batteries are found in some Stellantis vehicles (i.e. Citroen, Opel, Peugeot, etc).

- In 2025 CATL announced a 'dual power' battery.

- Sodium-LFP Dual-Power Battery: Combines sodium-ion with LFP self-forming anode technology, enhancing cold-weather performance and range.

- LFP-LFP Dual-Power Battery: Integrates second-generation Shenxing fast-charging battery with LFP self-forming anode battery, achieving up to 800 km range (WLTP).

- NCM-LFP/NCM-NCM Dual-Power Battery: Pairs NCM batteries with either LFP or NCM self-forming anode batteries, enabling fast charging (12C), high power output (over 1 MW peak), and extended ranges exceeding 1,200 km (WLTP).

In addition, CATL have the Shenxing Superfast Charging LFP Battery: featuring 650 km range (WLTP) and a 12C peak charging rate (can charge at up to 1.3 MW).

What's LMR?

LMR (Lithium Manganese Rich) is a high manganese, very low cobalt cell. With high energy capacity, the challenge is cycle life. In 2025 a joint venture between LG and GM was announced, intending to bring to production by 2027.

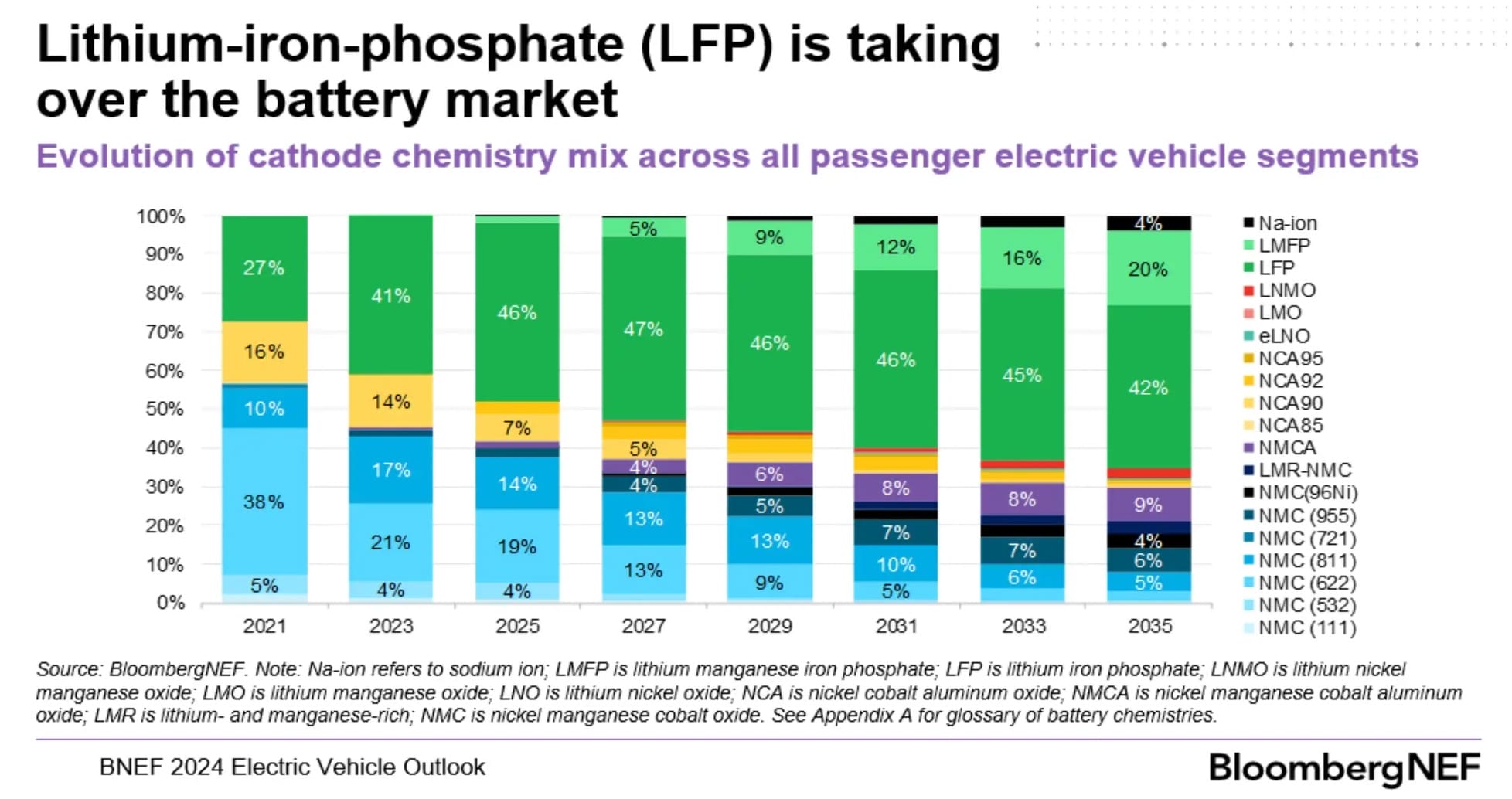

What's the outlook for LFP batteries?

A report by BloombergNEF suggests that over half of EVs delivered in 2027 will have LFP chemistry - including the newer LMFP (Lithium Manganese Iron Phosphate).

LMFP has a higher energy density but a slightly lower cycle life than LFP.

While currently more expensive, it has better thermal stability than nickel-based chemistries.

New Zealand specific models (available new) with LFP batteries

← Swipe to scroll horizontally →

Model & Variant | Usable Battery (kWh) | Range (km) | Price | |

|---|---|---|---|---|

BYD Atto 1 Essential | LFP | 30 kWh | 220 km | $29,990 |

BYD Atto 1 Premium | LFP | 43.2 kWh | 310 km | $35,990 |

BYD Atto 2 Dynamic | LFP | 51.1 kWh | 345 km | $39,990 |

BYD Atto 2 Premium | LFP | 51.1 kWh | 345 km | $45,990 |

BYD Atto 3 Essential | LFP | 50 kWh | 345 km | $49,990 |

BYD Atto 3 Superior | LFP | 60.5 kWh | 420 km | $55,990 |

BYD Dolphin Essential | LFP | 44.9 kWh | 340 km | $39,990 |

BYD Dolphin Premium | LFP | 60.5 kWh | 427 km | $48,990 |

BYD Seal Dynamic | LFP | 61.4 kWh | 460 km | $58,990 |

BYD Seal Performance | LFP | 82.6 kWh | 520 km | $76,990 |

BYD Seal Premium | LFP | 82.6 kWh | 570 km | $65,990 |

BYD Sealion 7 Performance | LFP | 82.5 kWh | 456 km | $79,990 |

BYD Sealion 7 Premium | LFP | 82.5 kWh | 482 km | $67,990 |

Dongfeng 007 Long Range | LFP | 70.3 kWh | 520 km | $54,990 |

Dongfeng 007 Performance | LFP | 70.3 kWh | 389 km | $59,990 |

Dongfeng Box | LFP | 43.9 kWh | 317 km | $29,990 |

Dongfeng Vigo | LFP | 51.9 kWh | 340 km | $37,990 |

Farizon SV LWB | LFP | 83 kWh | 344 km | $84,990 |

Farizon SV LWB High | LFP | 83 kWh | 328 km | $89,990 |

Farizon SV SWB | LFP | 83 kWh | 376 km | $79,990 |

Farizon SV SWB base | LFP | 67 kWh | 303 km | $74,990 |

GAC Aion V | LFP | 75.3 kWh | 510 km | $49,990 |

GAC Aion V Lux | LFP | 75.3 kWh | 510 km | $51,990 |

Geely EX5 Complete | LFP | 60.2 kWh | 430 km | $49,990 |

Geely EX5 Inspire | LFP | 60.2 kWh | 410 km | $53,990 |

Geely Riddara RD6 | LFP | 73 kWh | 360 km | $69,990 |

GWM Ora GT | LFP | 57.7 kWh | 380 km | $39,990 |

GWM Ora Lux | LFP | 57.7 kWh | 400 km | $36,990 |

Jaecoo J5 EV | LFP | 58.9 kWh | 402 km | $42,990 |

Kia EV5 Earth | LFP | 84 kWh | 540 km | $75,450 |

Kia EV5 Earth AWD | LFP | 84 kWh | 500 km | $80,450 |

Kia EV5 GT-Line | LFP | 84 kWh | 470 km | $85,450 |

Kia EV5 Light | LFP | 84 kWh | 555 km | $67,990 |

Kia EV5 Light plus | LFP | 84 kWh | 555 km | $70,450 |

LDV eDeliver 9 | LFP | 68.9 kWh | 236 km | $69,990 |

Leapmotor B10 Design | LFP | 65 kWh | 434 km | $47,990 |

Leapmotor B10 Life | LFP | 55 kWh | 361 km | $42,990 |

Leapmotor C10 | LFP | 66 kWh | 420 km | $52,990 |

Leapmotor C10 AWD | LFP | 81.9 kWh | 437 km | $64,990 |

MG 4 Excite 51 | LFP | 50.8 kWh | 350 km | $40,990 |

MG IM6 Premium | LFP | 73.5 kWh | 450 km | $66,900 |

MG S5 EV 49 Essence | LFP | 49 kWh | 335 km | $48,990 |

MG S5 EV 49 Excite | LFP | 49 kWh | 340 km | $44,990 |

MG S5 EV 62 Essence | LFP | 62 kWh | 425 km | $54,990 |

MG S5 EV 62 Excite | LFP | 62 kWh | 430 km | $50,990 |

Omoda E5 BX | LFP | 58.9 kWh | 430 km | $36,990 |

Omoda E5 EX | LFP | 58.9 kWh | 430 km | $44,990 |

Tesla Model 3 Premium RWD | LFP | 60.9 kWh | 520 km | $63,900 |

Tesla Model Y Premium RWD | LFP | 60.5 kWh | 466 km | $67,900 |

XPeng G6 AWD Performance | LFP | 80 kWh | 510 km | $72,990 |

XPeng G6 RWD | LFP | 80 kWh | 525 km | $63,990 |

Zeekr 7X RWD | LFP | 71 kWh | 480 km | $69,990 |